MACHINERIES AND STATE-OF-THE-ART TECHNOLOGIES

Thanks to continuous investments in human and technical resources, Tecnottica is able to provide and certify the manufacturing and the polishing of optical surfaces with the highest standards available in the optical market.

PRECISION OPTICS

Grinding, polishing and optical centering at their best

A huge part of Tecnottica’s production is now dedicated to the manufacturing of plano and spherical optical components who require very tighten optical and geometrical tolerences; these elements are usually inserted in machine vision systems, imaging systems and in setups for laser applications.

The precision optics department, built into a separated area of our plant in Calco, has been studied in a way that can operate independently from the rest of the production. Through this philosophy Tecnottica protects and guarantees the respect of tolerances and lead times of all its product lines by differentiating his own offer directly starting from the production area itself.

Thanks to constant investments in state-of-the-art machinery, Tecnottica is able to generate, polish and center optical surfaces (with diameters ranging from 2.7 to 310 mm (0,106in to 12,205in) and with the highest standards currently allowed by the technology of the sector we can obtain flatness values up to lambda / 20, while Optical cementing and combined centering of achromatic doublets are guaranteed with centerings below 30”.

Our precision optics department is equipped with:

- Schneider SLG301

- Schneider OM SLG50

- Schneider OM SLG120

- Schneider OM SCGA100

- LOH Spheromatic 120 SL

- Satisloh SPM-200

- Schneider SLP301

- Optotech SPK100

- Optotech SPK150

- Schneider OM 120SL

- Satisloh SPS125

- Stock Konstruction RSP 20-3

- Stock Konstruction RSP 40-2

- Optotech HM300

- Satisloh SPS-200

- Optotech ZM200 CNC

- Satisloh C50

- Loh CM2 SL

- Optotech AZP2 HP

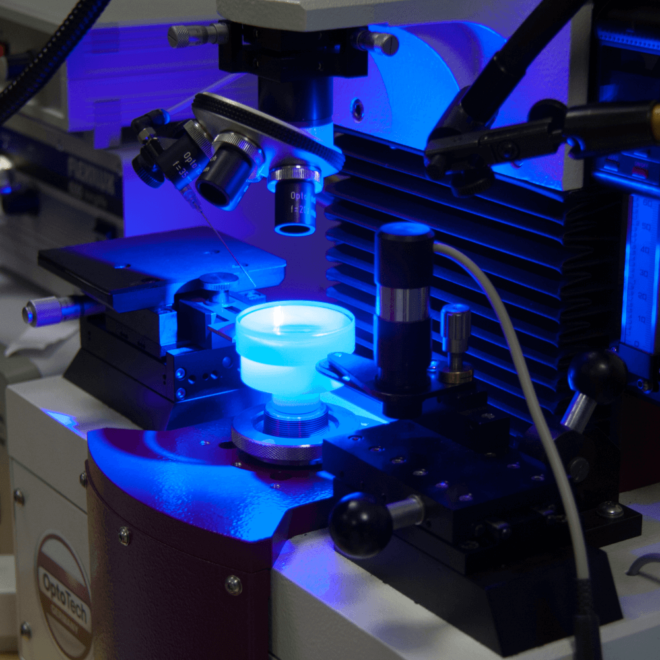

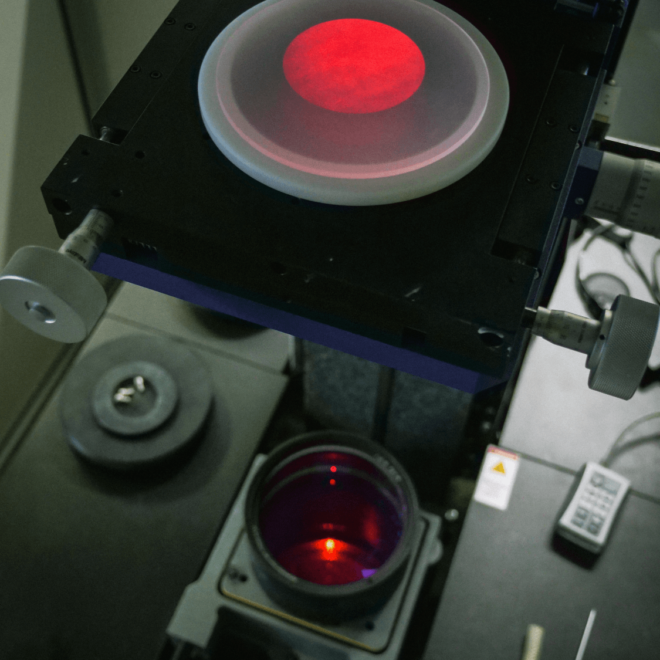

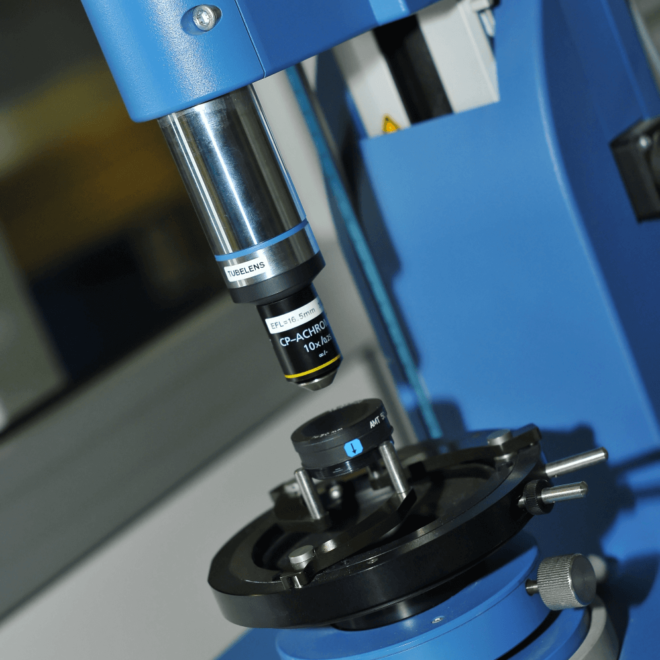

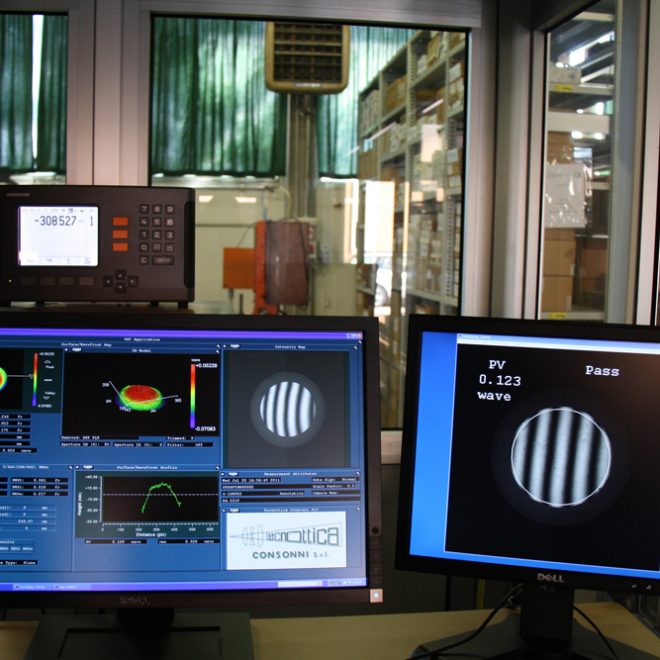

METROLOGY AND CONTROL

Complete and effective controls of every single step of the manufacturing process

The metrology and control department, adjacent and complementary to the production area, has been specifically designed to have complete and effective control after each stage of the processing of our precision products. Through this philosophy we are able to offer our customers a range of products with the highest quality, certified and guaranteed by our tools, while reducing waste and manufacturing defects.

Tecnottica's metrology departmet is equipped with:

- Interferometer Schneider SLI 101 equipped with hardware Zygo 4”

- Interferometer Optotech OWI 150 XT equipped with hardware Zygo 6” and software Zygo Metro Pro

- Interferometer XONOX VT1200 4”

- Interferometer XONOX VT1200 6” equipped with hardware Zygo 6” and software Zygo MX

- Transmission spheres for 4” and 6” interferometers

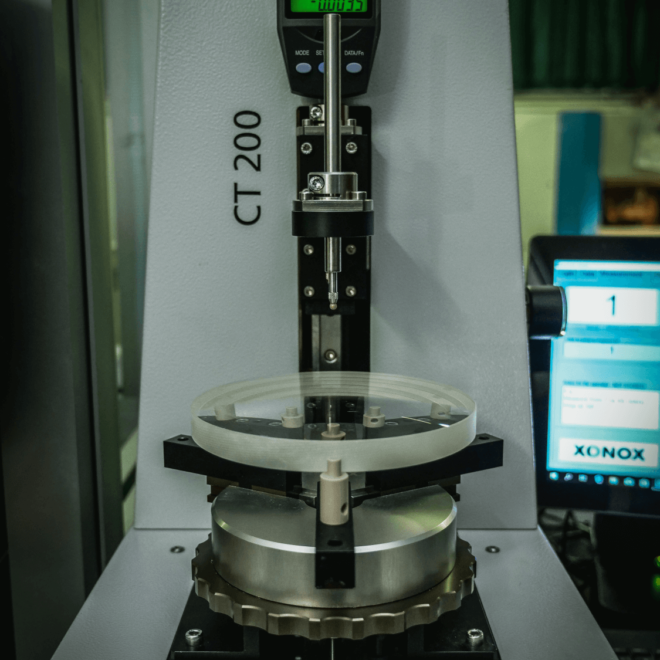

- Thickness measurer XONOX CT200

- Trioptics OptiSpheric

- Trioptics SpheroCompact

- Trioptics PM150MAN

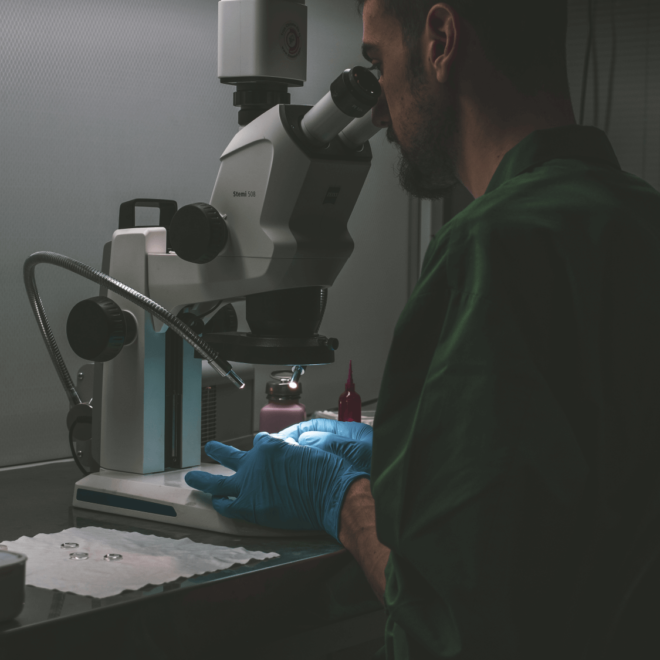

- ZEISS 50X microscope with integrated camera and analysis sofware

- 3D Optical Profiler System ZeGage Pro

- MarForm MFU 200 Aspheric 3D

Thanks to our equipment, we are able to certify to our customers the following measurements:

- Radii of curvature measurements with sub-micrometric accuracy

- Measurements of prisms and wedges

- Measurements of thicknesses and sagitta values

- Measurements of EFL of single elements and complete systems

- Measurements of resolution and MTF curve of complete systems (performed @546 nm)

- Interferometric analysis of optical surfaces, in accordance with ISO 10110 standards

- Cosmetic defects analysis of optical surfaces, in accordance with ISO 10110 standards

- Measurements of the roughness of optical surfaces up to 0.15 nm