Maximum precision is the goal of all our processes and our metrology room is what allows us to certify the results we are able to obtain.

Over the years we have expanded the metrology and control department, adjacent and complementary to the production area, ensuring maximum quality in dimensional control and interferometric control.

The evolution of the production department was accompanied by a corresponding evolution of the metrology department, pursuing the objective of expanding the variety and complexity of the projects to be implemented, and at the same time raising the degree of precision to certify the quality of lenses made.

Tecnottica's metrology department is equipped with:

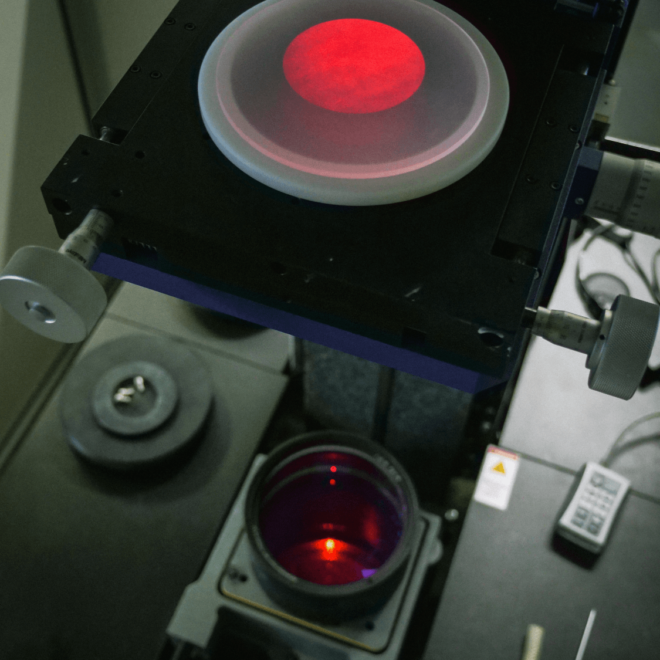

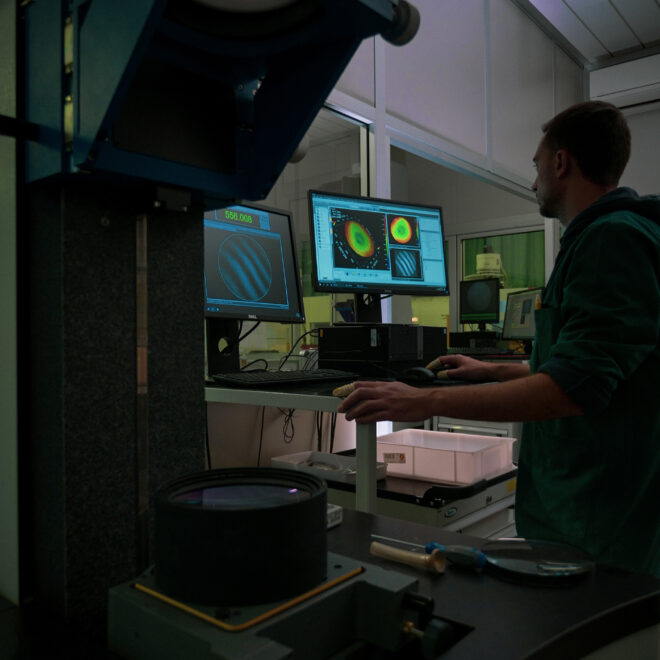

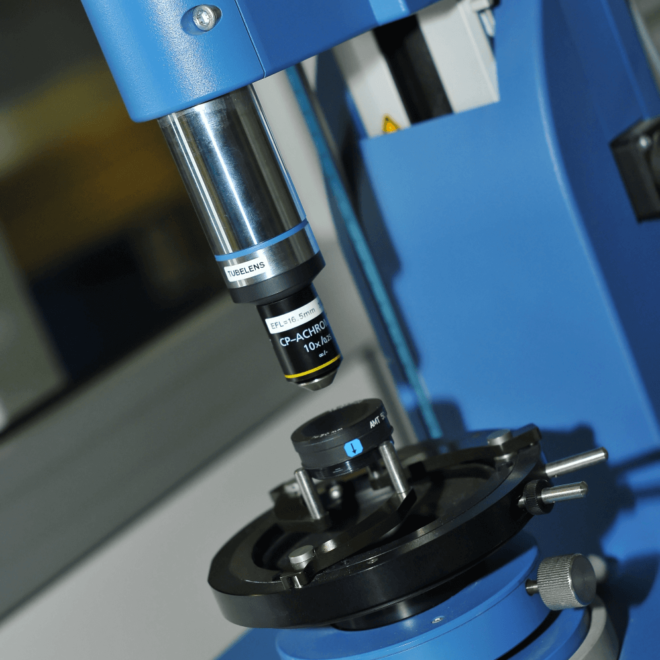

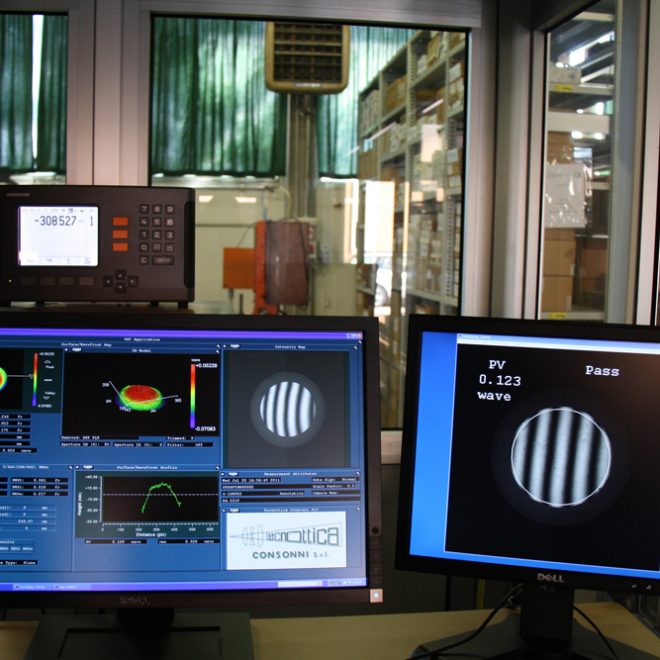

- Interferometer Schneider SLI 101 equipped with hardware Zygo 4”

- Interferometer Optotech OWI 150 XT equipped with hardware Zygo 6” and software Zygo Metro Pro

- Interferometer XONOX VT1200 4”

- Interferometer XONOX VT1200 6” equipped with hardware Zygo 6” and software Zygo MX

- Transmission spheres for 4” and 6” interferometers

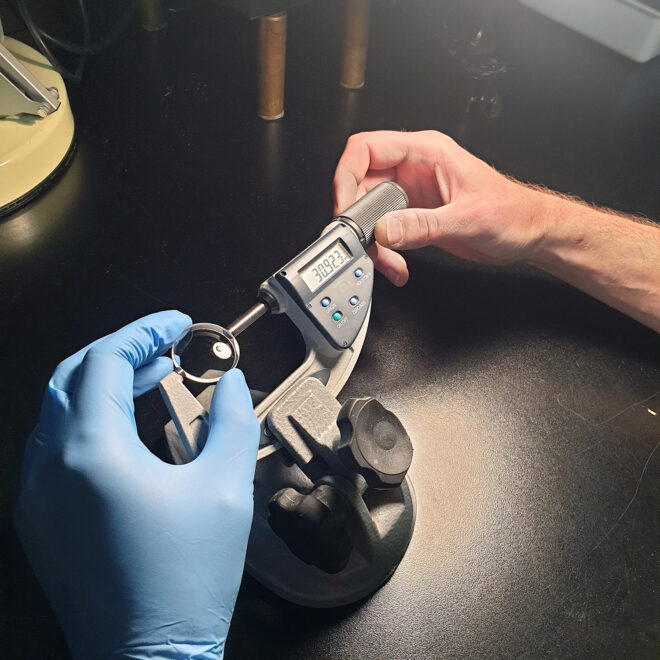

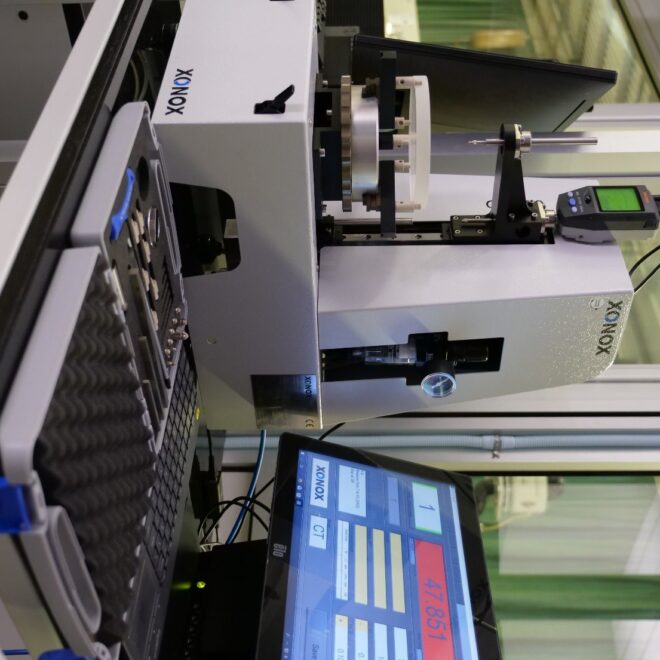

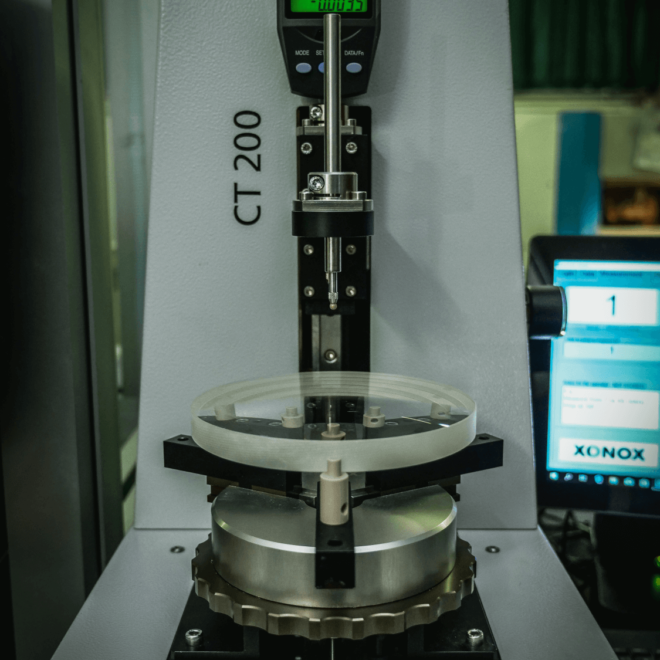

- Thickness measurer XONOX CT200

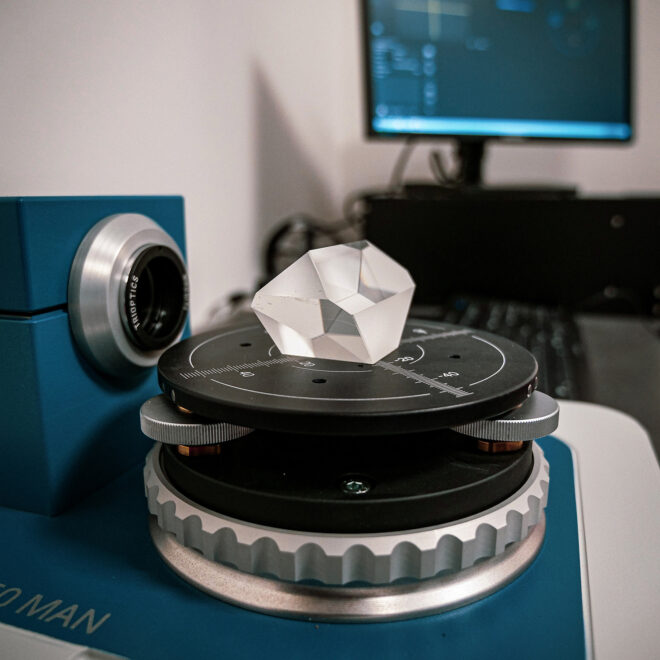

- Trioptics OptiSpheric

- Trioptics SpheroCompact

- Trioptics PM150MAN

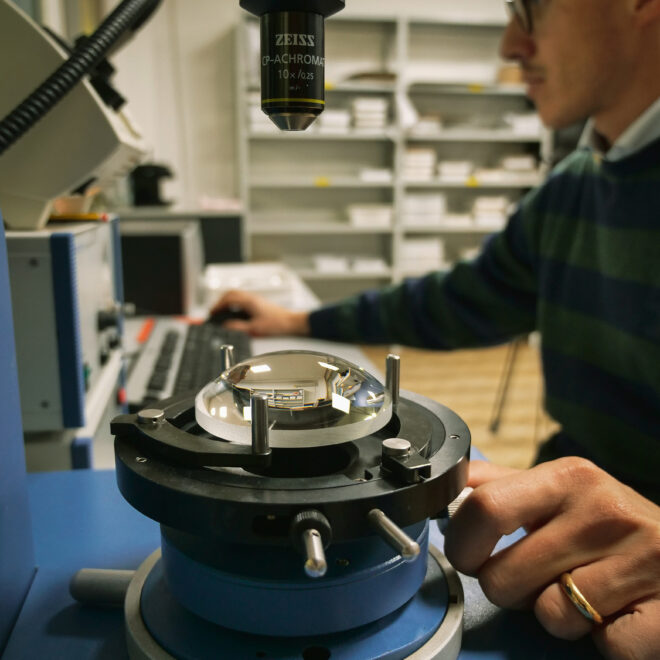

- ZEISS 50X microscope with integrated camera and analysis sofware

- Spectrophotometer EssentOptics PHOTON RT 190-4900

The machinery and equipment listed ensure a high level of precision but require specific skills, which in Tecnottica are consolidated through years of experience and constant updating aimed at innovation. Tools and skills allow us to carry out and certify the following measurements to our customers:

- Radii of curvature measurements with sub-micrometric accuracy

- Measurements of prisms and wedges

- Measurements of thicknesses and sagitta values

- Measurements of EFL of single elements and complete systems

- Measurements of resolution and MTF curve of complete systems (performed @546 nm)

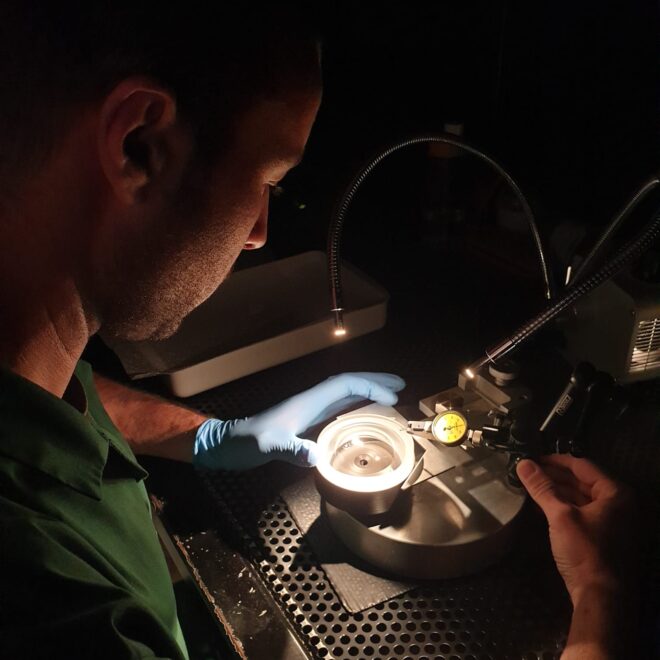

- Interferometric analysis of optical surfaces, in accordance with ISO 10110 standards

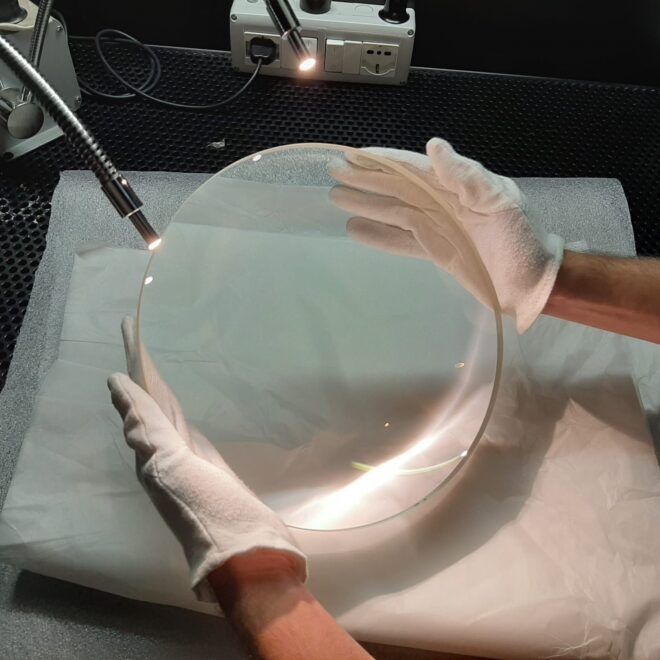

- Cosmetic defects analysis of optical surfaces, in accordance with ISO 10110 standards

We have made precision our hallmark.

We perform a complete check of all the processes, and we do it both directly during the production process and by carrying out a final test of all the elements before and after the application of any treatments.

Thanks to continuous checks we are not only able to offer our customers a range of products with the highest quality, certified and guaranteed by high precision skills and instruments, but we are also able to improve the lens production process, reducing waste and manufacturing defects.